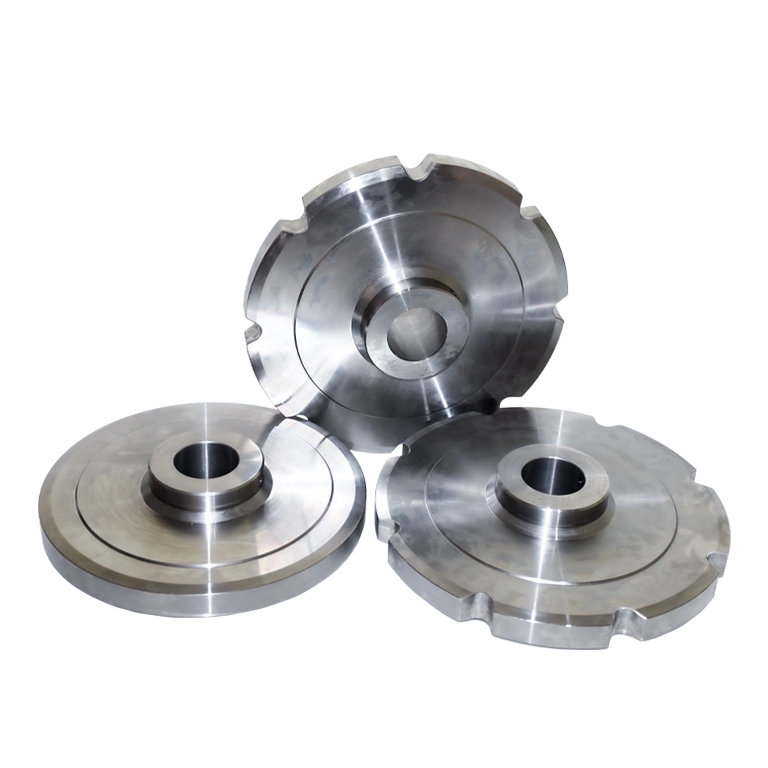

Chain Sprocket

What is a Chain Sprocket? Types of Chain Sprockets and Advantages of Chain Sprockets

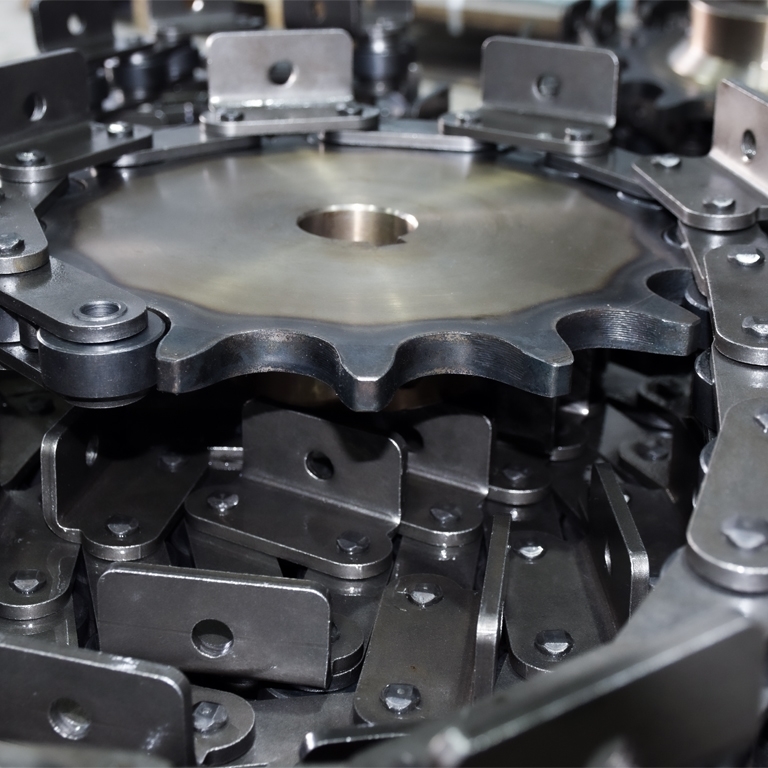

Sprockets are used in motion transmission mechanisms that work in conjunction with chains. Due to their sprocket pitch structures, they work in harmony with chains.

There are varieties such as single row chain sprocket, double row chain sprocket, triple row chain sprocket, four row chain sprocket, induction chain sprocket, stainless chain sprocket, conveyor chain sprocket and plastic chain sprocket.

The advantages of chain sprockets include the fact that they require little lubrication, transmit power and motion over long distances, can be used outdoors, and are suitable for special production according to different areas of use and different customer requests, and for this reason, chain sprockets are highly preferred.

We manufacture and deliver chain sprockets and chain sprocket dimensions to suit different areas of use and special productions you desire.

Chain Sprocket Usage Areas

The use of chain sprockets is not limited to which we mostly see on bicycles in daily life. It is also used in motorcycle and automobile chains, as well as in chains in the machine industry, garage door chains, and textile machine and escalator chains. Compared to other chains, chain sprockets, which are more intertwined with daily life, have a very wide customer profile. Chain sprockets, which offer different uses according to different areas, are produced according to the system they are suitable for.

BKC Chain Sprocket Manufacturing and Sprocket Dimensions

BKC Chain has the capacity to manufacture the sprockets of all the chains it manufactures. BKC Chain sprockets work in perfect harmony with BKC chains, thus contributing to the chains working smoothly for many more years.

Offering special production options according to the chain dimensions requested by its customers in chain sprockets manufacturing, BKC Chain is among the most preferred sprockets.

In different cases, plastic material is used and stainless steel is also produced. BKC chain sprockets, which are produced with good workmanship, continue to work for long periods as they work in harmony with the chains. In carbon steel chain production, the working life of the chain sprockets is extended by hardening the tooth profiles.

For chain sprockets that require regular lubrication and maintenance for their high performance operation, maintenance should be provided in such a way that all friction surfaces are lubricated. It can be used for a long time with sufficient and regular lubrication.